drag

Fish Crazy

im making a sump for my tank but i was wondering about the plumbing involved. is there some special type of glue for the pvc pipes and fittings or is the regular primer and regular glue safe to use?

April FOTM Photo Contest Starts Now!

🏆 Click to enter! 🏆

Cool, How long should it take the glue to fully cure to where the chemicals wont harm the fish? .... i cant wait

and any special precaution like washing in fresh water before use or something?

How strange. I can't recall even ever seeing a primer for sale over here, let alone ever thought about using one.Yeah, quite reef safe, just use the regular stuff. I wouldn't gamble by NOT priming...

)

)

late night at about 10:30 i was watching the 1939 old wizard of Oz rerun when bam it hit me

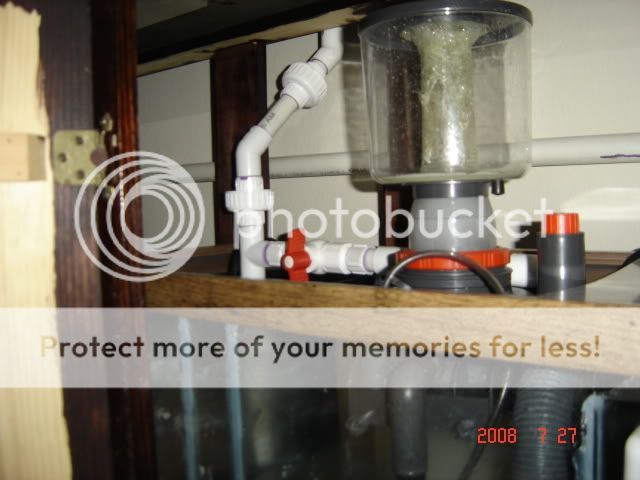

late night at about 10:30 i was watching the 1939 old wizard of Oz rerun when bam it hit me  the drain is awsome fast, so fast that the bubble it was creating in the overflow now travel all the way though the other side. thats right no trapped bubbles.Dare i open it more

the drain is awsome fast, so fast that the bubble it was creating in the overflow now travel all the way though the other side. thats right no trapped bubbles.Dare i open it more